- Home Page

- Company Profile

-

Our Products

- Microtomes

- Microscopes

- Audio Visual Projections

- Clean Air Systems

- Heat and Refrigeration Systems

- Refrigerated Equipments

- Blood Banking Instruments

- General Laboratory Products

- Pharmaceutical Laboratory Equipment

- Pharmacology Products

- Psychology Lab Equipments

- Fluid Mechanic Labs

- Medical Anatomy Instruments

- Chemical Engineering Laboratory Equipments

- Analytical Instruments

- Soil Testing Equipments

- Building and Civil Engineering Equipments

- Teaching lab Equipment

- Hydraulic Fluid Mechanics Lab Equipments

- Applied Mechanics Gyroscope Models

- Mechanism Models

- Bitumen Testing Instruments

- Meteorological Instruments

- Gear Box Model

- Applied Mechanics Lab Equipments

- Laboratory Testing Equipments

- Machanics lab

- Steam Condenser Models

- Engineering Educational Equipments

- Brake Models

- Belt Pulley Models

- Bearing Models for Engineering Students

- Key & Joints Models

- Coupling Models

- Clutch Models

- Electrical Lab Equipment

- Internal combustion Exhaust Gas Analyzing Unit

- Fuel Supply System Of Automobile

- Miscellaneous Products

- Model of Steering

- Differential Gear Models

- Agricultural Laboratory Equipments

- Actual Cut Section Engines

- Electrical Lab Trainer Equipments

- Power Engines And Machines for Engineering Student

- Microprocessor And Microcontroller Lab

- Working Model Engines

- Car Engine Petrol & Diesel

- MODELS OF DIFFERENT CLUTCHES

- Automobile Engineering Models

- Educational Training Equipment

- Screw & Nut Models

- Gyroscope Models

- Object Drawing Models

- Heat Transfer Lab Equipments

- Working Models of Different Brakes

- Mass Transfer Lab Equipments

- Construction Machine Lab Equipment

- Strength of Material Testing Equipments

- Thermometer Baror

- Mountings & Accessories Of Steam Boilers

- Momentum Transfer Lab Equipments

- Refrigeration Air Conditioning Lab Equipments

- Actual Section Engine Model

- ACTUAL CUT SECTION CHASSIS MODEL

- AUTOMOBILE TEST RIGS

- Boiler Models

- Sectional Working Models Of Petrol & Diesel Engine

- Steam Engine Models

- Governor Models

- SteamTurbine Models

- Theory Of Machine Lab Equipments

- Test Sieves

- Petroleum testing Instruments

- Civil Engineering Bridge Road Models

- CULVERT MODELS

- RAILWAY MODELS

- Drawing Instruments

- BUILDING MODELS

- IRRIGATION MODELS

- PUBLIC HEALTH MODELS

- Material Testing Equipment

- Cement And Concrete Testing Equipment

- Asphalt Testing Equipments

- Laboratory Instruments

- Laboratory Autoclaves

- Clean Room Equipments

- Entomological Equipments

- Unit Mechanic Operation Lab

- Bricklaying and Plastering Tools

- Electronic Ignition System

- Plastering and Carpentry

- Electrical Equipment

- Control Engineering Lab

- Experimental Stress Analysis Lab

- Educational Equipments

- Vibration Lab Apparatus

- Chemistry Lab Instrument

- Construction Lab Equipment

- Mechanical & Maintenance Trainers

- Cut-Away Valves

- Acrylic Working Demonstrators

- Process Trainers

- Process Units

- Acrylic Static Models

- Rack Systems

- CNC Milling & Lathes Table Top Models

- Split Case Cut Away

- CNC Milling Cabinet Models

- CNC Milling Drilling Lathe Systems

- VLSI Lab

- Physics Lab Equipment

- Antenna, Satellite, Radar & RF Trainers

- Decade Box

- Digital Clamp Meters

- Digital Multimeter

- IC Testers & Programmers

- Lab Furniture

- Laboratory Plasticware

- Logic Probe

- Microwave Test Benches

- Digital Meters

- Embedded Microprocessor Trainers

- Digital Electronics Trainer

- DC Power Supplies

- Plumbing and sheet metal equipment

- Carpenter Tools

- Industrial Vices

- Garden Tools

- Leather Tools Bags

- Industrial Hacksaw

- Hospital Bed

- Hospital Stretchers

- Wheel Chairs

- Applied science Engineering

- Electrical Trainer Equipments

- Mechanical Lab Equipments

- Laboratory Glassware

- Biology Models

- Incinerator

- Mechanical and Metal Febrication

- Automobile Engineering Equipment

- Agriculture Equipment

- Laboratory Oven and Water Bath

- Our Export Market

- Contact Us

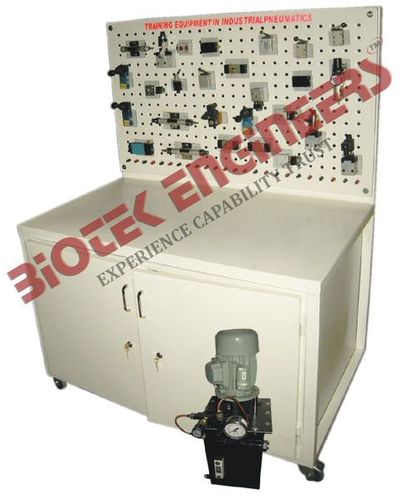

Training Equipment In Industrial Pneumatics

Product Details:

X

Product Description

Training Equipment In Industrial Pneumatics :Biotek Engineers is manufacture, exporters & suppliers of Training Equipment In Industrial Pneumatics.

Training Equipment In Industrial Pneumatics :

The set up comprises a Mobile Lab. Trolley, set of Pneumatic Components and a Comprehensive Manual.Mobile lab. trolley

- Approx. dim: 1210mm(L) x 750mm(W) x 1450mm(H).

- The trolley must have two (2) circuit building plugboards (approx. size) 1100mm x 700mm, each with mounting holes must be fitted with rubber component retaining grommets.

- The boards must be powder coated 16swg steel (at least), with 2mm shrouded sockets for electrical distribution built into the plugboard.

- There must be two (2) lockable equipment storage cabinets, each consists of five (5) drawers (depths are 1 x 66mm, 2 x 85mm, 1 x 130mm, 1 x 200mm - approx. sizes). Cabinets and all drawers to be steel, powder coated construction including drawer fronts.

- The trolley must be mounted on four (4) heavy duty, rubber tyred castors two (2) of which are swivel and lockable.

- The trolley must be mounted on four (4) heavy duty castors two(2) of which are swivel and lockable. Set of Components - Pneumatics, comprises:-

- 1 x Air service unit (filter/pressure regulator) with ON/OFF valve and pressure gauge

- 1 x 6-way manifold with check fittings (airflow blocked on removal of tubing)

- 1 x Single Acting Cylinder - 16mm diameter, 50mm stroke

- 2 x Double Acting Cylinder - 16mm diameter, 100mm stroke with magnetic piston for contactless sensing

- 4 x 3/2 way Push Button Valve (2 baseplates each with 2 valves)

- 1 x 3/2 way Toggle Lever Valve

- 1 x Visual Indicator

- 1 x 5/2 way Toggle Lever Valve

- 1 x 5/2 way Pilot/spring Valve

- 3 x 5/2 way Pilot/Pilot Valve

- 1 x 5/3 way Pilot/Pilot Valve with Closed centre

- 2 x 3/2 way Roller Lever Valve (for instroke operation) -mounted on adjustable baseplate (must have both vertical and horizontal adjustment).

- 2 x 3/2 way Roller Lever Valve (for outstroke operation) - mounted on adjustable baseplate (must have both vertical and horizontal adjustment).

- 1 x 3/2 way Adjustable Timer valve

- 2 x Throttle / Check Valve (on one baseplate)

- 1 x Quick Exhaust Valve

- 4 x Shuttle Valve / OR Gate (2 baseplates each with 2 valves)

- 2 x Two Pressure Valve / AND Gate (on one baseplate)

- 1 x Stainless Steel Air Reservoir

- 1 x Pressure Gauge

- 10 x Push-fit Tee

- 10 x Push-fit Plug

- 15 metres 4mm o.d. polyurethane tubing

- 5 metres 6mm o.d. polyurethane tubing

- All pneumatic components should mount on four (4) pin plug-in baseplate, complete ready to use with pneumatic connections for 4mm o.d. tubing (supplied) and 2mm shrouded plugs / sockets for electrical connections. All threaded exhaust ports to be fitted with silencers.

Other Products in 'Hydraulic Fluid Mechanics Lab Equipments' category

Contact Details

|

|

|

|

BIOTEK ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |