- Home Page

- Company Profile

-

Our Products

- Microtomes

- Microscopes

- Audio Visual Projections

- Clean Air Systems

- Heat and Refrigeration Systems

- Refrigerated Equipments

- Blood Banking Instruments

- General Laboratory Products

- Pharmaceutical Laboratory Equipment

- Pharmacology Products

- Psychology Lab Equipments

- Fluid Mechanic Labs

- Medical Anatomy Instruments

- Chemical Engineering Laboratory Equipments

- Analytical Instruments

- Soil Testing Equipments

- Building and Civil Engineering Equipments

- Teaching lab Equipment

- Hydraulic Fluid Mechanics Lab Equipments

- Applied Mechanics Gyroscope Models

- Mechanism Models

- Bitumen Testing Instruments

- Meteorological Instruments

- Gear Box Model

- Applied Mechanics Lab Equipments

- Laboratory Testing Equipments

- Machanics lab

- Steam Condenser Models

- Engineering Educational Equipments

- Brake Models

- Belt Pulley Models

- Bearing Models for Engineering Students

- Key & Joints Models

- Coupling Models

- Clutch Models

- Electrical Lab Equipment

- Internal combustion Exhaust Gas Analyzing Unit

- Fuel Supply System Of Automobile

- Miscellaneous Products

- Model of Steering

- Differential Gear Models

- Agricultural Laboratory Equipments

- Actual Cut Section Engines

- Electrical Lab Trainer Equipments

- Power Engines And Machines for Engineering Student

- Microprocessor And Microcontroller Lab

- Working Model Engines

- Car Engine Petrol & Diesel

- MODELS OF DIFFERENT CLUTCHES

- Automobile Engineering Models

- Educational Training Equipment

- Screw & Nut Models

- Gyroscope Models

- Object Drawing Models

- Heat Transfer Lab Equipments

- Working Models of Different Brakes

- Mass Transfer Lab Equipments

- Construction Machine Lab Equipment

- Strength of Material Testing Equipments

- Thermometer Baror

- Mountings & Accessories Of Steam Boilers

- Momentum Transfer Lab Equipments

- Refrigeration Air Conditioning Lab Equipments

- Actual Section Engine Model

- ACTUAL CUT SECTION CHASSIS MODEL

- AUTOMOBILE TEST RIGS

- Boiler Models

- Sectional Working Models Of Petrol & Diesel Engine

- Steam Engine Models

- Governor Models

- SteamTurbine Models

- Theory Of Machine Lab Equipments

- Test Sieves

- Petroleum testing Instruments

- Civil Engineering Bridge Road Models

- CULVERT MODELS

- RAILWAY MODELS

- Drawing Instruments

- BUILDING MODELS

- IRRIGATION MODELS

- PUBLIC HEALTH MODELS

- Material Testing Equipment

- Cement And Concrete Testing Equipment

- Asphalt Testing Equipments

- Laboratory Instruments

- Laboratory Autoclaves

- Clean Room Equipments

- Entomological Equipments

- Unit Mechanic Operation Lab

- Bricklaying and Plastering Tools

- Electronic Ignition System

- Plastering and Carpentry

- Electrical Equipment

- Control Engineering Lab

- Experimental Stress Analysis Lab

- Educational Equipments

- Vibration Lab Apparatus

- Chemistry Lab Instrument

- Construction Lab Equipment

- Mechanical & Maintenance Trainers

- Cut-Away Valves

- Acrylic Working Demonstrators

- Process Trainers

- Process Units

- Acrylic Static Models

- Rack Systems

- CNC Milling & Lathes Table Top Models

- Split Case Cut Away

- CNC Milling Cabinet Models

- CNC Milling Drilling Lathe Systems

- VLSI Lab

- Physics Lab Equipment

- Antenna, Satellite, Radar & RF Trainers

- Decade Box

- Digital Clamp Meters

- Digital Multimeter

- IC Testers & Programmers

- Lab Furniture

- Laboratory Plasticware

- Logic Probe

- Microwave Test Benches

- Digital Meters

- Embedded Microprocessor Trainers

- Digital Electronics Trainer

- DC Power Supplies

- Plumbing and sheet metal equipment

- Carpenter Tools

- Industrial Vices

- Garden Tools

- Leather Tools Bags

- Industrial Hacksaw

- Hospital Bed

- Hospital Stretchers

- Wheel Chairs

- Applied science Engineering

- Electrical Trainer Equipments

- Mechanical Lab Equipments

- Laboratory Glassware

- Biology Models

- Incinerator

- Mechanical and Metal Febrication

- Automobile Engineering Equipment

- Agriculture Equipment

- Laboratory Oven and Water Bath

- Our Export Market

- Contact Us

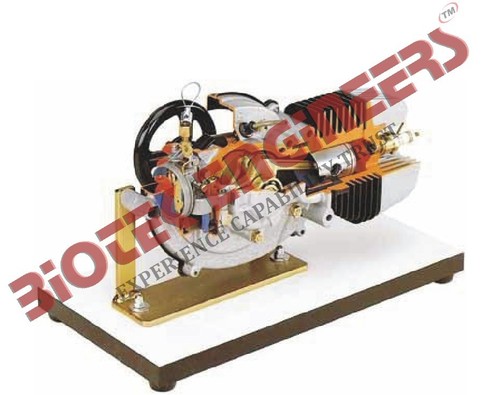

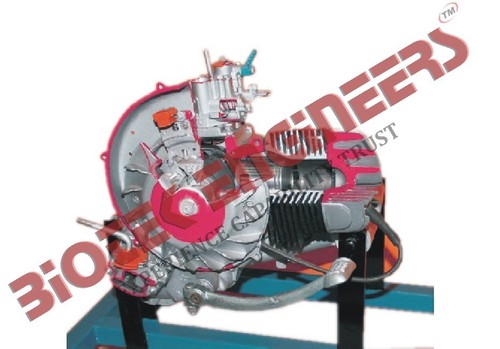

4 Stroke 1 Cylinder Vertical Diesel Engine

Product Details:

X

Product Description

4 Stroke 1 Cylinder Vertical Diesel Engine

Biotek Engineers is manufacture, exporters & suppliers of: 4 Stroke 1 Cylinder Vertical Diesel Engine

The setup consists of single cylinder, four stroke, Diesel engine connected to eddy current / Hydraulic type dynamometer for loading. It is provided with necessary instruments for combustion pressure and crank-angle measurements. These signals are interfaced to computer through engine indicator for PQ - PV diagrams.

Provision is also made for interfacing airflow, fuel flow, temperatures and load measurement. The set up has stand-alone panel box consisting of air box, fuel tank, manometer, fuel measuring unit, transmitters for air and fuel flow measurements, process indicator and engine indicator. Rotameters are provided for cooling water and calorimeter water flow measurement.

The setup enables study of engine performance for brake power, indicated power, frictional power, BMEP, IMEP, brake thermal efficiency, indicated thermal efficiency, Mechanical efficiency, volumetric efficiency, specific fuel consumption, A/F ratio and heat balance. Lab view based Engine Performance Analysis software package "Engine soft LV" is provided for on line performance evaluation. A computerized Diesel injection pressure measurement is optionally provided.

Engine: Type 1 cylinder, 4 stroke Diesel, water cooled, power 5.2 kW at 1500 rpm, stroke 110 mm, bore 87.5 mm. 661 cc, CR 17.5

Dynamometer

Product 224:Type eddy current, water cooled

Product 224H:Type Hydraulic

Propeller shaft: With universal joints

Air box: M S fabricated with orifice meter and manometer

Fuel tank: Capacity 15 lit with glass fuel metering column

Calorimeter: Type Pipe in pipe

Piezo sensor: Range 5000 PSI, with low noise cable

Crank angle sensor: Resolution 1 Deg, Speed 5500 RPM with TDC pulse.

Data acquisition device: NI USB-6210, 16-bit, 250kS/s.

Piezo powering unit: Make-Cuadra, Model AX-409.

Temperature sensor: Type RTD, PT100 and Thermocouple, Type K

Temperature: Type two wire, Input RTD PT100, Range 0 - 100 DegC,

transmitter: I/P Thermocouple, Range 0 - 1200 DegC, O/P 4 - 20mA

Load indicator: Digital, Range 0-50 Kg, Supply 230VAC

Load sensor: Load cell, type strain gauge, range 0-50 Kg

Fuel flow transmitter: DP transmitter, Range 0-500 mm WC

Air flow transmitter: Presure transmitter, Range (-) 250 mm WC

Software: "EnginesoftLV" Engine performance analysis software

Rotameter: Engine cooling 40-400 LPH; Calorimeter 25-250 LPH

Pump: Type Monoblock

Overall dimensions: W 2000 x D 2500 x H 1500 mm

Optional: Computerized Diesel injection pressure measurement

Other Products in 'Actual Cut Section Engines' category

Contact Details

|

|

|

|

BIOTEK ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |